Lapping Guidelines

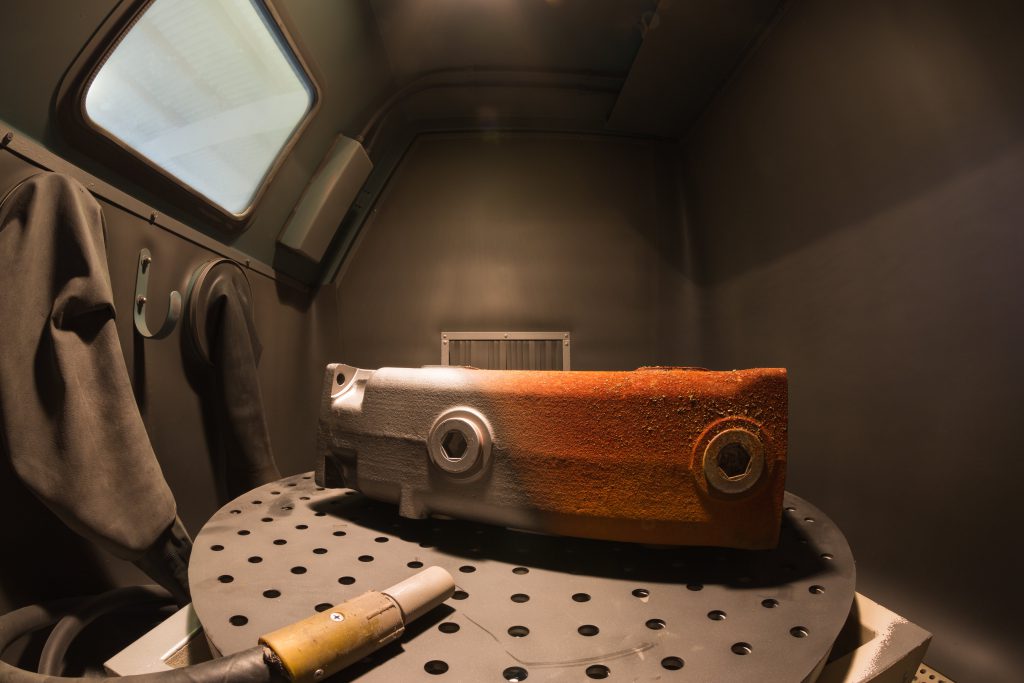

These guidelines are intended to help control the abrasive slurry used in the lapping process. Following these suggestions will help to bring this variable in the lapping process under greater control. Consistent stock removal and surface finish quality result in a predictable product, and the consistency of the abrasive slurry is critical in the lapping process.

1. Slowly add the abrasive into the slurry while stirring the mixture.

2. Slurries are typically

- Water

- Oil

- Water + Additive (Additives are usually liquids that help to suspend and/or act as a corrosion inhibitor)

3. K. C. Abrasive Powders come three ways:

- Untreated, designated as MA, OP, CFP, AO

- Suspension Treated, designated as ST

- Treated, designated as T

4. Suspension treated (ST) should be mixed with water only. Do not mix with water and another vehicle.

5. Suspension treated (ST) abrasive powders are typically used when recirculating the slurry.

6. Mix “ST” abrasive 1.5 to 2.5 lbs. per gallon of water.

7. Recommended starting mix ratio: 2 lbs. per gallon.

8. K. C. Abrasive “ST” (Suspension Treated) is comparable to most competitors “T”.

9. Do not use “ST” (Suspension Treated) abrasive in a brush feed application.

10. All K. C. Abrasive Treatments are dry ingredients that have been blended into the abrasive so that it comes to our customers ready to be mixed with oil or water.

11. Treated “T” abrasive is typically mixed with oil or a water + additive mixture.

12. When adding fresh abrasive to a working slurry, it is recommended to premix a concentrated slurry, then add it to the existing slurry.

13. Where there are several lapping machines in use, we recommend that a central mixing tank is used to mix the slurry, then draw off slurry for each individual machine.

For more information on the Lapping Process click here.

Glossary

Aluminum Oxide Powder

K. C. Abrasive’s precise brown fused powder for lapping, grinding, compounding, and blasting applications. (See also: Aluminum Oxide Powder Product Page.)

AO

Ordering code for Aluminum Oxide Powder.

CFP

Ordering code for Crystal Finishing Powder.

Crystal Finishing Powder

K. C. Abrasive’s original formulation for quartz crystal lapping. (See also: Crystal Finishing Powder Product Page.)

FEPA

The Federation of European Producers of Abrasives. The FEPA standards for bonded (F series) and coated (P series) abrasives have generally been accepted on a worldwide basis. K. C. Abrasive typically sells abrasives graded to the F series specification.

Lapping

The use of abrasives to shape a parts and blanks with high dimensional accuracy, reduced shape imperfections, a smoother surface, improved parallelism, and a better part-to-part fit. (See above: Lapping Guidelines )

MA

Ordering code for Micro Alumina.

Macrogrit

Any abrasive grit 240 or coarser. (See also: Grit and Powder Sizing, macrogrit)

Micro Alumina

K. C. Abrasive’s premium quality, calcined alumina for lapping applications. (See also: Micro Alumina Product Page.)

Microgrit

Any abrasive grit 280 or finer. (See also: Grit and Powder Sizing, microgrit)

OP

Ordering code for Optical Powder.

Optical Powder

K. C. Abrasive’s exacting powder for wholesale ophthalmic and precision lens industries. (See also: Optical Powder Product Page.)

Screen

A tightly controlled wire mesh used to separate abrasives into distinct size ranges. Used to manufacture macrogrits.

Sieve

A sieve is a mounted screen.

Slurry

A mixture of solids and liquids. In the case of abrasive slurries, this is usually an oil or water based compound with the abrasive particles suspended in it. Thickeners, lubricants, corrosion inhibitors, and biocides are often added to improve the properties of the slurry. (See above: Lapping Guidelines )

ST Treatment

ST is used to designate our “suspension treatment” formula for water only base slurries. It is recommended for re-circulating/central slurry systems. It is designed to retard settling, provide soft sediment, form a lubricating film to protect the part and improve surface finish. Available at no additional charge. (See also: T treatment.)

T Treatment

T is used to designate our “treated” formula that is principally for oil based slurries. It may also be used with water base slurries + liquid suspension additives. It is designed to provide a lubricating film that reduces drag and eliminates galling which helps to protect the part and improve surface finish. Available at no additional charge. (See also: ST treatment.)

Water classification

K. C. Abrasive uses a process of water classification to separate their powders. The technical term for water classification is “elutriation”.